The Fiebr 4-in-1 Laser Welding Machine with Wire Feeder is a versatile and advanced welding system designed for precision welding applications. Here is an overview of its key features and capabilities:

Key Features:

4-in-1 Multi-Functionality – Combines four essential welding functions in one machine:

Laser Welding – High-precision welding with minimal heat distortion.

Wire Feeding – Allows for filler material addition, improving joint strength and gap filling.

Cleaning Function – Removes oxidation and impurities before welding.

Other possible functions (depending on model): Some versions may include TIG-like welding, spot welding, or engraving.

Fiber Laser Technology – Uses an IPG or similar high-quality fiber laser source for stable, efficient, and deep penetration welding.

Wire Feeder System – Enables the addition of filler wire (stainless steel, aluminum, etc.) for stronger welds and better gap bridging.

High Precision & Speed – Ideal for thin materials (0.1mm–6mm) with minimal thermal deformation.

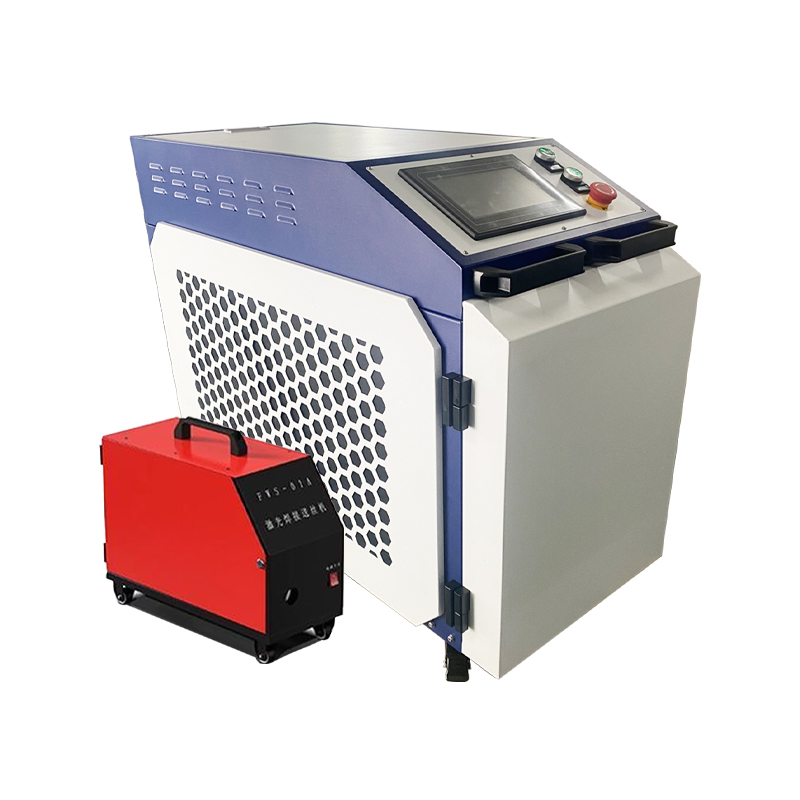

User-Friendly Interface – Touchscreen or digital control panel for easy parameter adjustments (power, pulse frequency, wire speed).

Wide Material Compatibility – Works on stainless steel, carbon steel, aluminum, copper, titanium, and more.

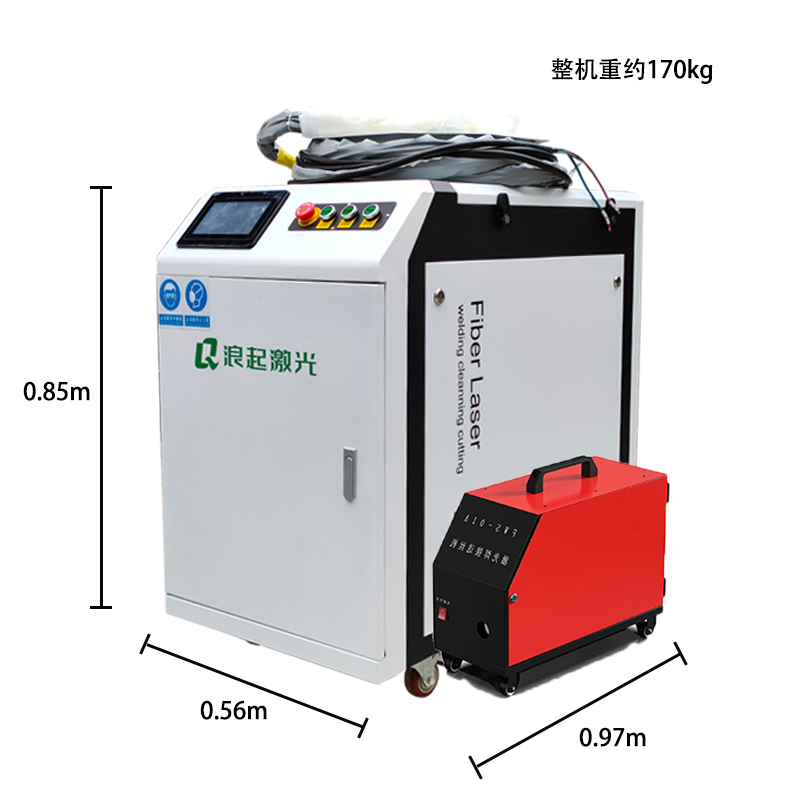

Portable & Compact Design – Some models are lightweight and easy to move.

Safety Features – Includes protective goggles, emergency stop, and cooling system.

Typical Applications:

Jewelry & Dental Welding

Automotive & Aerospace Repairs

Electronics & Battery Welding

Tool & Mold Repair

Thin Sheet Metal Fabrication