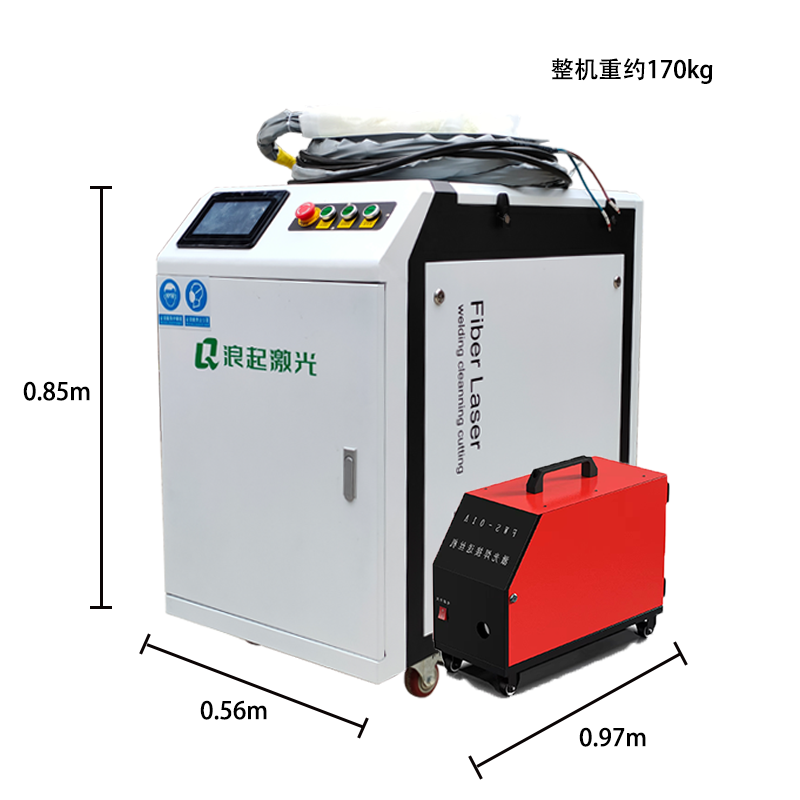

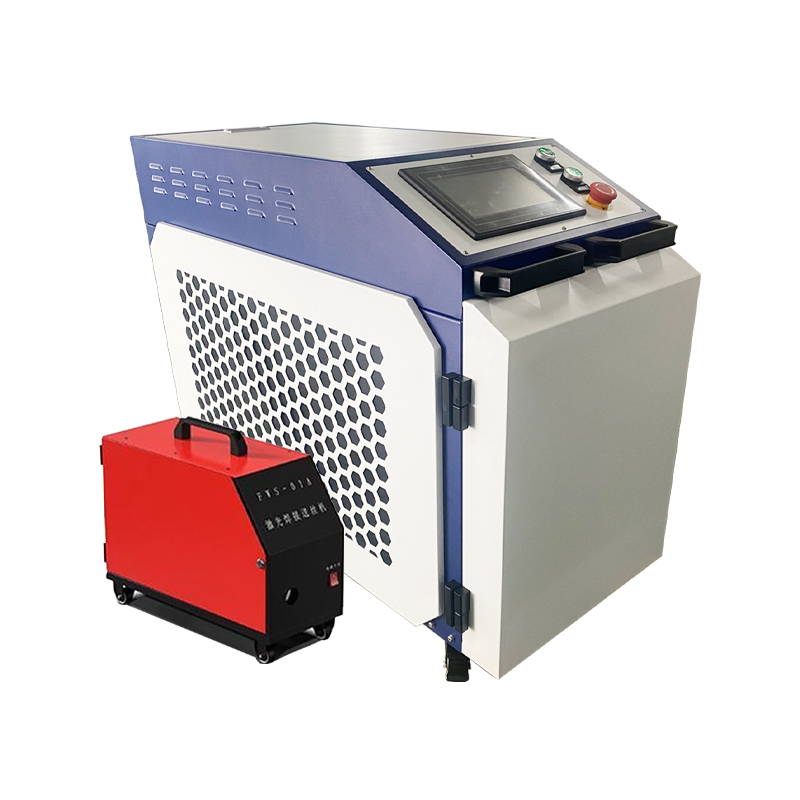

The Fiebr Laser Welding 4-in-1 Machine is a versatile industrial equipment that integrates multiple functions, typically including laser welding, cleaning, cutting, and surface hardening. This all-in-one system is designed for efficiency, precision, and cost-effectiveness in various manufacturing and repair applications.

Key Features of the 4-in-1 Machine:

Laser Welding

High-precision welding for metals (stainless steel, aluminum, copper, etc.).

Minimal heat-affected zone (HAZ), reducing material distortion.

Suitable for delicate or complex components (jewelry, electronics, automotive parts).

Laser Cleaning

Removes rust, oxides, paint, and contaminants without damaging the base material.

Eco-friendly alternative to sandblasting or chemical cleaning.

Used in restoration, automotive, and aerospace industries.

Laser Cutting

Precision cutting of thin to medium-thickness metals.

Smooth edges with high accuracy (useful for sheet metal fabrication).

Laser Surface Hardening

Improves wear resistance and durability of metal parts.

Localized heat treatment without affecting the entire component.

Applications Across Industries:

Automotive & Aerospace: Repairing engine parts, turbine blades, and lightweight alloys.

Electronics: Micro-welding of batteries, sensors, and circuit components.

Jewelry & Precision Manufacturing: Fine welding of delicate items.

Mold & Die Repair: Fixing high-value molds with minimal distortion.

Maintenance & Restoration: Cleaning and refurbishing historical artifacts or machinery.