A small fiber laser cleaning machine is an efficient, eco-friendly tool for deep cleaning steel materials, removing rust, paint, oxide layers, and contaminants without damaging the base material. Here are how it works and its benefits:

How It Works

Laser Ablation Process:

The fiber laser emits high-intensity pulses that vaporize contaminants (rust, paint, oil) on the steel surface.

The base material remains unharmed due to precise wavelength control (typically 1064nm).

Non-Abrasive & Contactless:

No physical contact means no surface wear or deformation.

Ideal for delicate or precision steel parts.

Adjustable Settings:

Power (50W-500W for small machines), frequency, and scanning speed can be tuned for different cleaning depths.

Key Benefits for Steel Cleaning

✔ Removes: Rust, mill scale, oil, coatings, oxides, and welding residues.

✔ No Chemicals or Media: Eco-friendly, no sandblasting or solvents needed.

✔ Precision Cleaning: Targets specific areas without masking.

✔ Fast & Efficient: Faster than manual grinding/sandblasting.

✔ Long-Term Cost Savings: Low maintenance, no consumables.

Applications

Automotive: Cleaning engine parts, chassis.

Manufacturing: Pre-weld/pre-paint steel surface prep.

Restoration: Removing corrosion from tools, machinery, historical artifacts.

Aerospace & Shipbuilding: Precision cleaning of steel components.

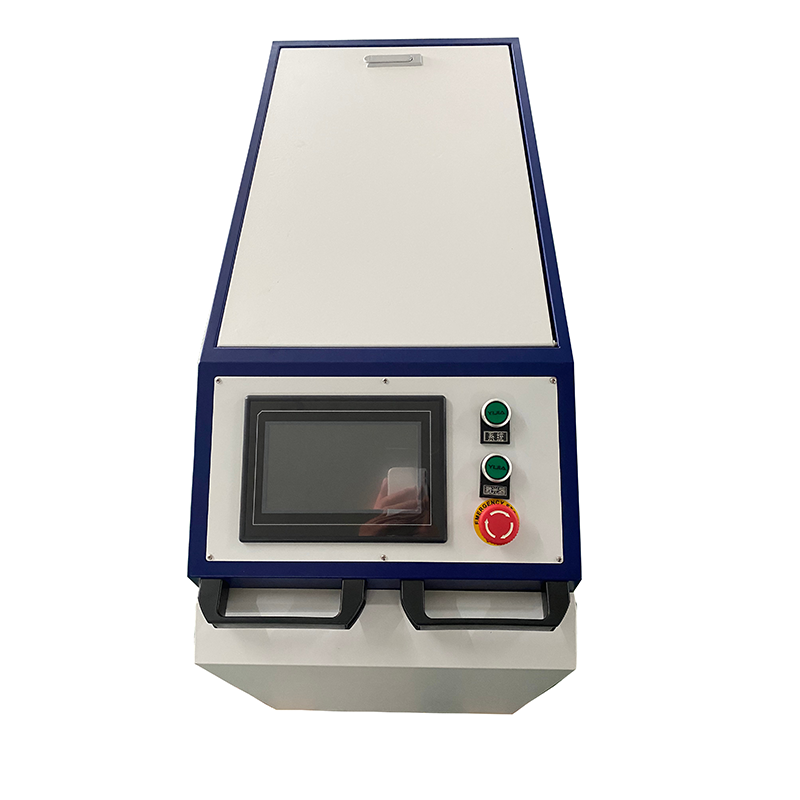

Machine Recommendations (Small Models)

Handheld Fiber Laser Cleaners (100W-300W) – Portable, easy to operate.

Benchtop Systems (200W-500W) – For small to medium steel parts.