Of course. Here is a detailed overview of a "4-in-1 Fiber Laser Machine" for cleaning, welding, cutting, and rust removal, specifically in the context of warehouse use.

Overview of the 4-in-1 Fiber Laser Machine

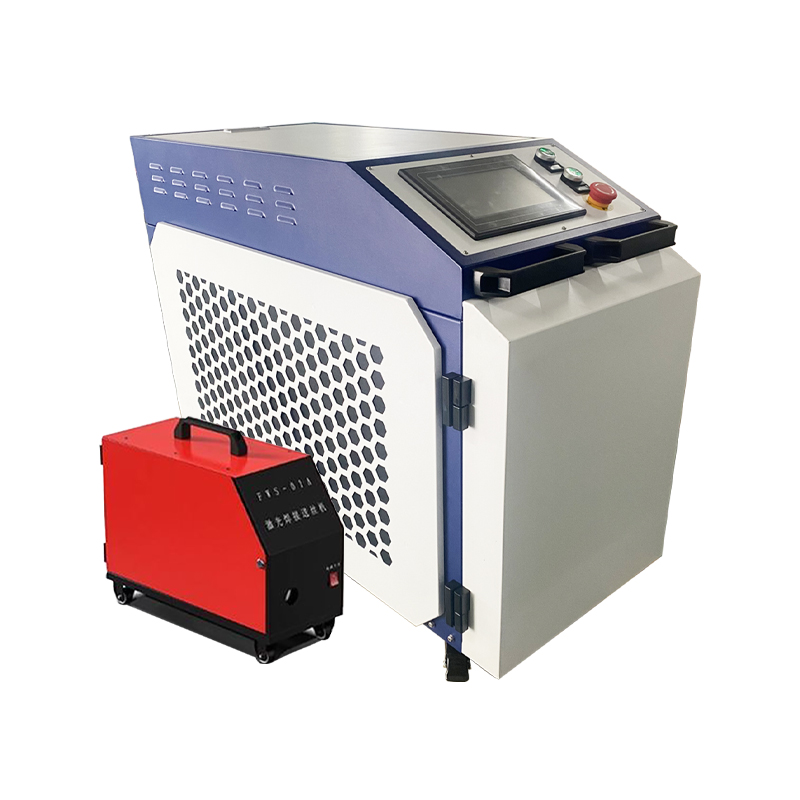

This type of machine is a highly versatile industrial tool that integrates four key metal processing functions into a single, compact system. It leverages the power of a fiber laser source, typically ranging from 500W to 2000W (or more), and uses different laser processing heads and software modes to switch between applications.

For a warehouse environment, this multi-functionality is a significant advantage, saving space, capital investment, and training time for operators who can now manage multiple tasks with one piece of equipment.

Key Components of the System

Fiber Laser Source: The heart of the machine. It generates a high-intensity laser beam that is delivered through a flexible fiber optic cable.

Laser Processing Head: A interchangeable head that focuses the laser beam onto the workpiece. Different heads are optimized for cutting, welding, or cleaning.

CNC Motion System: This can be either:

Gantry System (for flat sheets): Ideal for fixed, large-area cleaning or precise cutting/welding of sheet metal stored in the warehouse.

Robotic Arm (6-axis): Offers maximum flexibility for cleaning, welding, or cutting on complex, three-dimensional parts (e.g., machinery, structural components).

Chiller Unit: Essential for cooling the laser source to ensure stable operation and long lifespan.

Fume Extraction System: Critical for warehouse safety to remove harmful fumes and particles generated during all four processes.

Control Software: The user interface allows operators to easily switch between modes (Clean, Weld, Cut, Rust Remove) and set the specific parameters for each job.

Breakdown of Each Function in a Warehouse Context

1. Laser Cleaning & Rust Removal

How it Works: The laser beam ablates (vaporizes) contaminants like rust, paint, oil, and coatings from the metal surface. The underlying metal, which has a higher vaporization threshold, remains unharmed. A built-in vacuum system collects the ejected particles.

Warehouse Applications:

Tool & Equipment Refurbishment: Cleaning rust and grime from old tools, jigs, forklift parts, and shelving before inspection or reuse.

Surface Preparation: Perfectly preparing metal surfaces for welding or painting, ensuring strong, high-quality bonds without chemical solvents or abrasive media that create mess.

Parts Restoration: Cleaning old inventory or returned metal parts to make them look new and saleable.

Benefits: Non-abrasive, no consumables (like sandblasting media), eco-friendly, and creates no secondary waste. It's precise and can automate the cleaning of large shelves or floors.

2. Laser Welding

How it Works: The laser beam creates a concentrated heat source that melts the metal at the joint, fusing pieces together with a very narrow and deep weld seam.

Warehouse Applications:

Repair & Maintenance: Fixing cracks in racks, shelving, forklift attachments, and metal containers on-site.

Fabrication: Custom building brackets, frames, carts, and storage solutions from metal stock held in the warehouse.

High-Precision Joining: For any value-added services the warehouse might offer, like assembling kits or products.

Benefits: Low heat distortion, high speed, and exceptional weld quality. Minimal post-weld cleanup is needed.

3. Laser Cutting

How it Works: The focused laser beam melts, burns, or vaporizes the metal along a programmed path, often assisted by a jet of gas (like nitrogen or oxygen) to blow away the molten material and create a clean cut.

Warehouse Applications:

On-Demand Fabrication: Cutting shelving parts, replacement components, signs, or templates directly from sheet metal stored in inventory without outsourcing.

Modification: Quickly altering metal racks, containers, or tools to fit specific needs.

Nesting: Efficiently cutting multiple parts from a single sheet of metal to minimize waste.

Benefits: Extremely high precision, smooth edges (often no finishing needed), and ability to cut complex shapes.

Advantages for Warehouse Operations

Space Efficiency: One machine replaces multiple dedicated systems (a sandblaster, a MIG/TIG welder, a plasma cutter), freeing up valuable floor space.

Cost Savings: Reduces the need for outsourcing repairs, fabrication, or cleaning. Eliminates consumable costs for cleaning (media, chemicals) and reduces gas and energy costs compared to traditional methods.

Versatility & agility: Enables the warehouse team to handle a vast array of tasks in-house, from maintenance to custom projects, making the operation more self-sufficient and responsive.

Improved Safety & Cleanliness: Laser cleaning is non-abrasive and generates no toxic chemical waste. The enclosed nature of many systems (especially gantry types) helps contain the process. This is a major benefit over messy sandblasting or grinding.

Precision & Quality: Delivers professional, high-quality results in all four applications, which is crucial for maintenance and fabrication work that needs to be durable and reliable.

Considerations Before Implementation

Initial Investment: These are advanced systems with a significant upfront cost. A strong business case based on ROI from saved outsourcing and efficiency gains is needed.

Training: Operators will require proper training to switch between the different functions and to program jobs safely and effectively.

Safety: Class 4 Laser Safety is paramount. This requires strict protocols: interlocks, enclosed work areas, laser-safe signage, and mandatory protective eyewear for anyone in the vicinity. The warehouse must have a dedicated, controlled space for the laser.

Power Requirements: The system will require a robust electrical connection and a compressed air or gas supply.