A Fiber Laser Welding Machine with Feeding Wires and Accessories is a high-precision welding system that uses a fiber laser source to join metals with the addition of filler wire for improved strength and gap filling. This setup is commonly used in industries requiring high-quality welds, such as automotive, aerospace, electronics, and medical device manufacturing.

Key Features of the System:

Fiber Laser Source

High-power (e.g., 500W–2000W) IPG, Raycus, or JPT laser.

Wavelength: 1070–1080 nm (ideal for metals like stainless steel, aluminum, copper, titanium).

High beam quality for precise, deep, and fast welding.

Wire Feeding System

Automatic wire feeder with adjustable speed (for consistent filler material deposition).

Compatible with various wire diameters (e.g., 0.2mm–2.0mm).

Reduces porosity and improves weld strength.

Welding Head & Optics

Collimator and focusing lens for fine control.

Optional seam tracking for automated welding.

CCD camera or microscope for real-time monitoring.

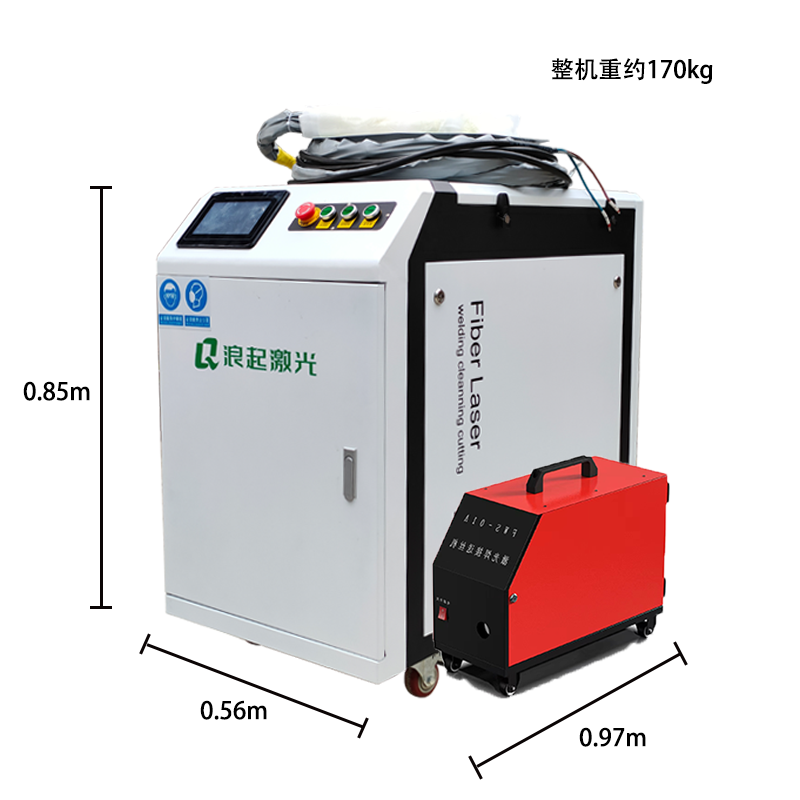

Cooling System

Chiller unit to maintain laser and optics temperature.

CNC or Robotic Integration

Can be mounted on robotic arms (e.g., KUKA, Fanuc) for automated production.

Compatible with XYZ motion stages for precision welding.

Accessories

Rotary table (for cylindrical parts).

Gas shielding kit (Argon/Helium to prevent oxidation).

Fume extraction system.

Touchscreen control panel.

Applications:

Automotive: Battery welding, sensors, exhaust systems.

Aerospace: Turbine blades, thin-walled components.

Electronics: Hermetic sealing, micro-welding.

Medical: Implants, surgical tools.

Jewelry & Precision Engineering: Fine welding with minimal heat distortion.