Of course. This is an excellent question, as the cost of a fiber laser marking machine varies dramatically. You can spend anywhere from $3,000 to over $60,000.

The price depends entirely on your specific application, required features, and the quality you need.

Here’s a detailed breakdown of the cost factors, typical price ranges, and what you get for your money.

Quick Answer: Price Tiers at a Glance

Entry-Level / Desktop Machines: $3,000 - $8,000

Mid-Range / Industrial Workhorses: $8,000 - $20,000

High-End / Advanced Performance: $20,000 - $60,000+

Detailed Breakdown of Cost Factors

1. Laser Source Power (The "Engine")

This is the most significant factor. Power is measured in Watts (W). More power is not always better—it's about matching the power to your material.

20W - 30W: The most common range for general-purpose marking on metals (stainless steel, aluminum, brass), plastics, and coated materials. Ideal for serial numbers, logos, barcodes, and annealing (black marks on stainless steel). This is the sweet spot for most businesses.

50W - 100W: Used for deep engraving into metals, cutting thin sheets, and high-speed production lines where marking time needs to be extremely fast.

<20W (e.g., 10W, 20W): Suitable for very fine marking on certain plastics or anodized aluminum. Less common and can be slower.

Cost Impact: A jump from a 20W to a 50W laser can add $5,000 - $10,000+ to the machine's cost.

2. Machine Brand & Origin

Western & Japanese Brands (e.g., Trumpf, Telesis, Trotec, Epilog): Premium pricing. You are paying for top-tier components, extensive R&D, robust software, exceptional reliability, and strong local technical support and warranty service. (Often $20,000+)

Chinese Brands with US/EU Support (e.g., Thunder Laser, Aeon Laser): Offer a strong middle ground. Good quality components assembled with better quality control than the budget tier, often with decent software and local warehouse support. ($8,000 - $25,000)

Budget Chinese Brands (e.g., generic machines from Alibaba, eBay): Lowest upfront cost. Quality control, components (like lenses and mirrors), and software can be inconsistent. Support and warranty claims can be very challenging. ($3,000 - $7,000) Buyer beware: these can be a false economy if used for critical production.

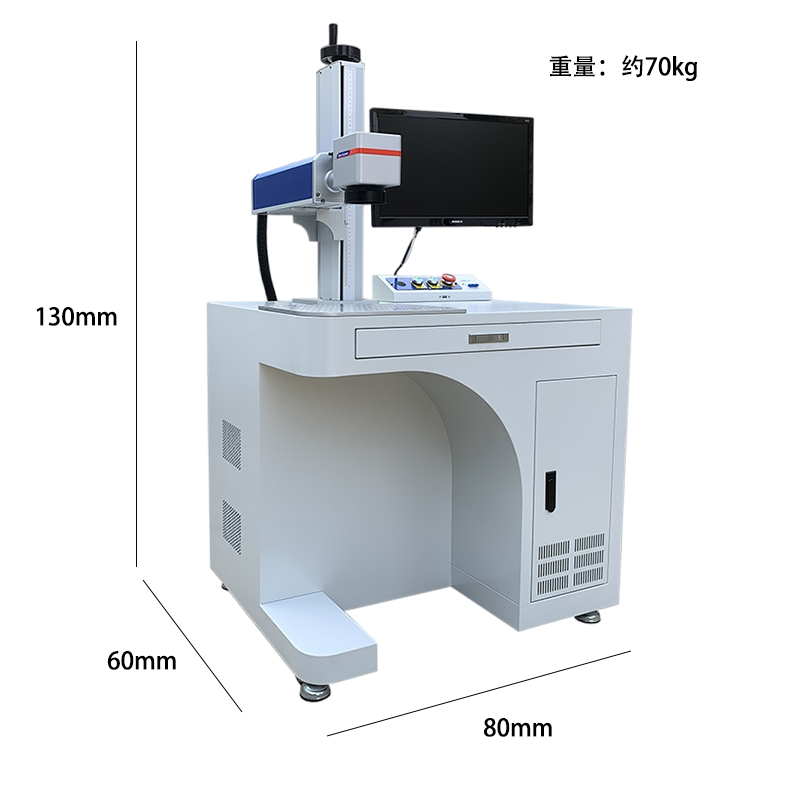

3. Machine Size & Workstation Type

Desktop / Benchtop Models: Smaller work area (e.g., 4" x 4" to 12" x 8"). Lower cost, suitable for small parts. ($3,000 - $10,000)

Standard Industrial Enclosed Cabinets: Most common. Medium to large work areas (e.g., 12" x 12" to 20" x 20"). Include safety interlocks, fume extraction, and a sturdy chassis. ($8,000 - $25,000)

Flying Optics / Galvo Systems: The laser head moves, not the material. Extremely fast marking speeds, perfect for assembly lines. ($15,000 - $40,000+)

Integrated Systems / Turnkey Cells: The laser is integrated into a fully automated production cell with robots part handling. ($40,000+)

4. Software

Basic OEM Software: Functional but can be clunky and limited in features. Common on budget machines.

Branded & 3rd Party Software (e.g., EzCad2 - very common, LightBurn): More user-friendly, powerful features for design, serialization, barcode generation, and database connectivity. EzCad is the industry standard for mid-range machines.

Premium Software (e.g., Trotec's JobControl): Exceptional user experience, advanced features, and seamless hardware integration.

Cost Impact: Good software is critical for productivity. A machine with a well-supported software package is worth the investment.

5. Additional Features & Accessories

Rotary Attachment: Essential for marking around cylindrical objects (pens, bottles, tubes). Adds $1,000 - $3,000.

CCD Camera Vision System: Automatically finds and aligns marks based on a part template. Crucial for high-volume precision work. Adds $4,000 - $10,000+.

Chiller: Required for higher-power lasers (>50W) to cool the laser source. Air-cooled is standard for lower-power machines.

Fume Extractor / Air Assist: Highly recommended for clean marks and operator safety. Can be integrated or separate.

Total Cost of Ownership (TCO)

The purchase price is not the only cost. Consider:

Maintenance: Lenses and mirrors need occasional cleaning and replacement. Higher-quality parts last longer.

Consumables: Chiefly electricity, but also gas for some lasers (though fiber lasers are very efficient).

Downtime: A cheap machine that breaks often can cost you more in lost production than a reliable expensive machine ever would.

Support: Having a technician available for setup and repairs is invaluable.

How to Determine What YOU Need

What materials will you mark? (e.g., stainless steel, anodized aluminum, plastic)

What is the mark? (e.g., surface etching, deep engraving, annealing)

What is your part size and shape? (Do you need a rotary attachment?)

What is your production volume? (A few parts a day vs. thousands per hour)

What is your budget? (Be realistic about both initial cost and long-term needs).

Recommendation

For a small shop or startup: A reputable 20W or 30W fiber laser from a supplier with good reviews and local support in the $7,000 - $12,000 range is an excellent investment that will handle 90% of common jobs.

Always request a sample mark on your actual material from any potential supplier before purchasing.