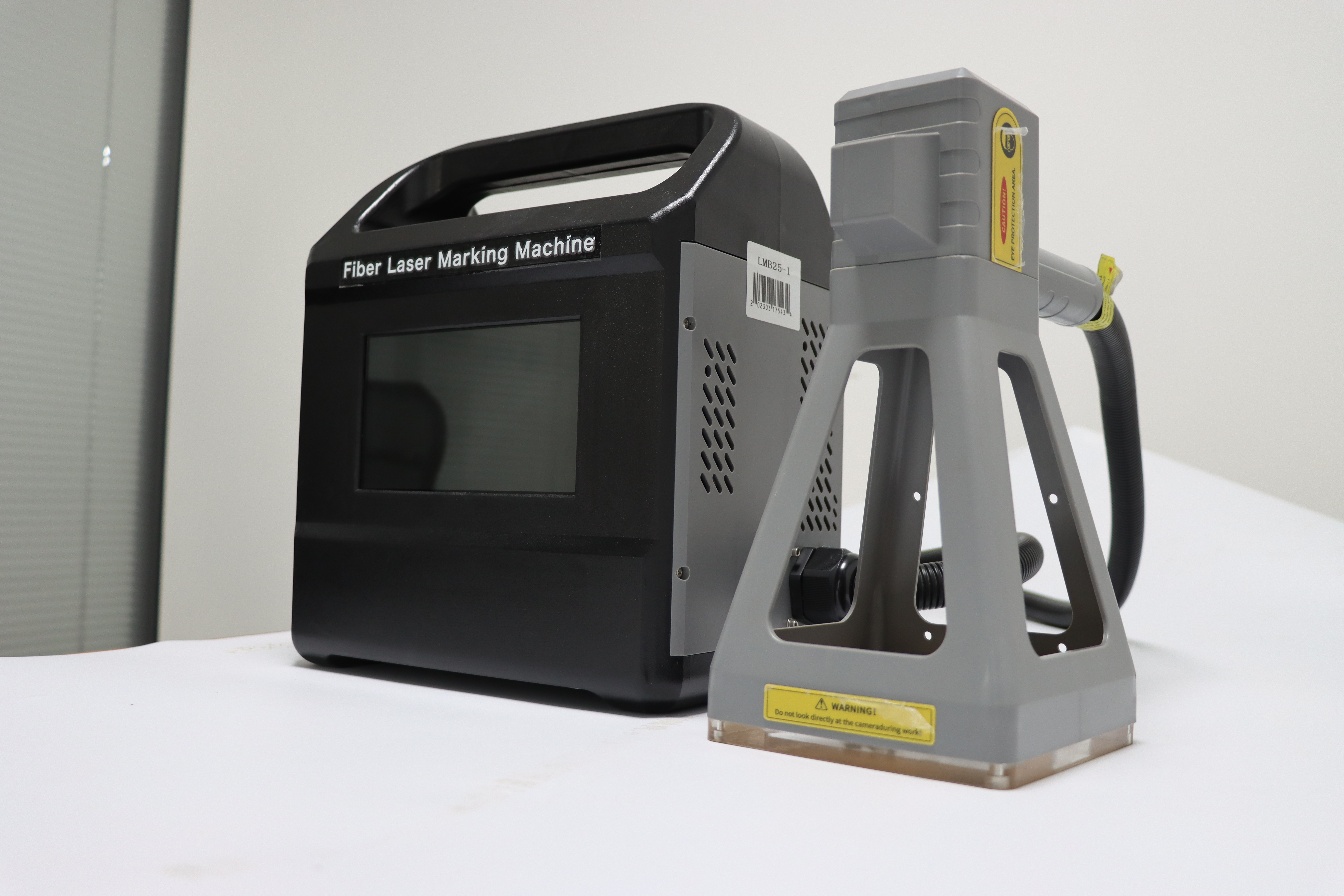

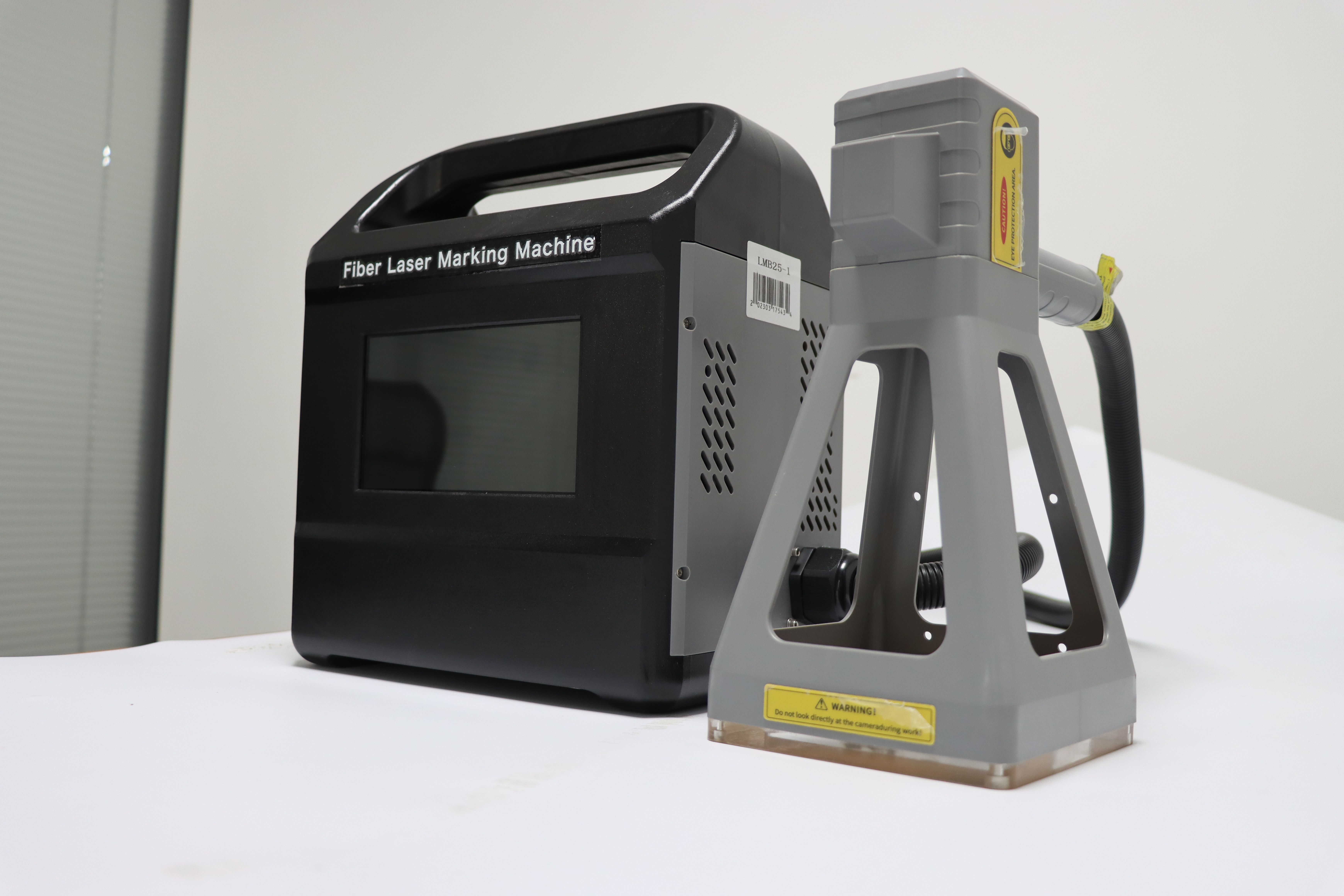

The handheld fiber laser marking machine is a portable device used for marking various materials (metals, plastics, ceramics, etc.). Below is a detailed step-by-step operation guide:

1. Safety Precautions

Wear protective glasses to avoid laser radiation.

Ensure the work area is well-ventilated.

Keep flammable materials away from the marking area.

Do not point the laser at people or reflective surfaces.

2. Machine Preparation

Power Connection:

Connect the machine to a stable power supply (AC 220V or as specified).

Turn on the main power switch.

Laser Check:

Ensure the laser head and cooling system are functioning properly.

3. Software Setup

Install Software:

Install the marking software (e.g., EZCAD, LaserMark) on a connected computer.

Connect to PC:

Link the machine to the computer via USB or network cable.

Design Marking Content:

Open the software and input text, logos, barcodes, or graphics.

Adjust parameters (font, size, spacing, etc.).

4. Parameter Adjustment

Laser Parameters:

Power: Adjust based on material (e.g., 20–60% for metals, 10–30% for plastics).

Frequency: Typically 20–100 kHz (higher for fine marks, lower for deep engraving).

Speed: Adjust marking speed (e.g., 100–2000 mm/s).

Pulse Width: Fine-tune for material compatibility.

Focus Adjustment:

Use the handheld device’s focus gauge or manual adjustment to set the optimal distance (e.g., 100–200 mm).

5. Test Marking

Place a sample material in the work area.

Perform a test mark and inspect the result.

Adjust parameters if the mark is too faint, too deep, or unclear.

6. Formal Marking

Position the handheld laser head perpendicular to the material surface.

Press the trigger (or start button) to begin marking.

Move steadily for consistent results (some models have auto-feed systems).

7. Post-Operation

Shutdown:

Turn off the laser, then the main power.

Disconnect the power supply.

Maintenance:

Clean the lens and laser head regularly with alcohol and a lint-free cloth.

Check for loose cables or debris.

8. Troubleshooting

No Laser Output: Check power, connections, and software settings.

Faint Marking: Increase power or reduce speed.

Overburning: Lower power or increase speed.

Misalignment: Recalibrate the laser head.