Laser marking machines are widely used in various industries for precision marking, engraving, and etching. They can be categorized based on the type of laser source they use. Here are the common types of laser marking machines:

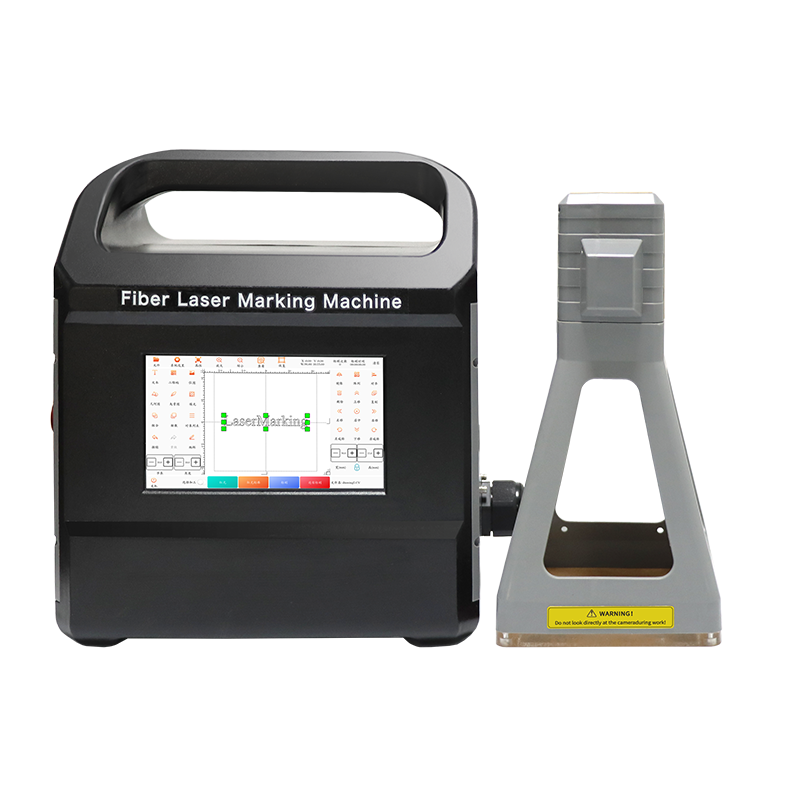

1. Fiber Laser Marking Machine

Laser Source: Fiber laser (1064 nm wavelength)

Best For: Metals (steel, aluminum, copper, brass), some plastics, and coated materials.

Applications:

Part serial numbers, barcodes, QR codes

Automotive & aerospace components

Jewelry and tool marking

Advantages:

High-speed marking

Long lifespan (100,000+ hours)

Low maintenance

2. CO₂ Laser Marking Machine

Laser Source: CO₂ gas laser (10.6 μm wavelength)

Best For: Non-metallic materials (wood, acrylic, glass, leather, plastics, rubber, paper).

Applications:

Packaging, food industry markings

Wood engraving & signage

Medical device labeling

Advantages:

Excellent for organic materials

Smooth engraving finish

3. UV Laser Marking Machine

Laser Source: Ultraviolet (UV) laser (355 nm wavelength)

Best For: Sensitive materials (plastics, glass, ceramics, silicone, PCB) requiring "cold marking" (minimal heat impact).

Applications:

Electronics (circuit boards, microchips)

Medical devices & pharmaceuticals

High-precision fine markings

Advantages:

No thermal damage to materials

High-resolution marking

4. Green Laser Marking Machine

Laser Source: Green laser (532 nm wavelength)

Best For: Highly reflective metals (gold, silver, copper), plastics, and sensitive materials.

Applications:

Jewelry engraving

Semiconductor & electronic components

Glass & crystal marking

Advantages:

Less heat dispersion

Fine detail marking

5. MOPA Laser Marking Machine

Laser Source: Adjustable pulse fiber laser (MOPA = Master Oscillator Power Amplifier)

Best For: Color marking on metals & plastics (e.g., stainless steel, anodized aluminum).

Applications:

High-contrast color engravings

Automotive & aerospace part labeling

Advantages:

Adjustable pulse duration for different effects

Can produce black/color marks on metal