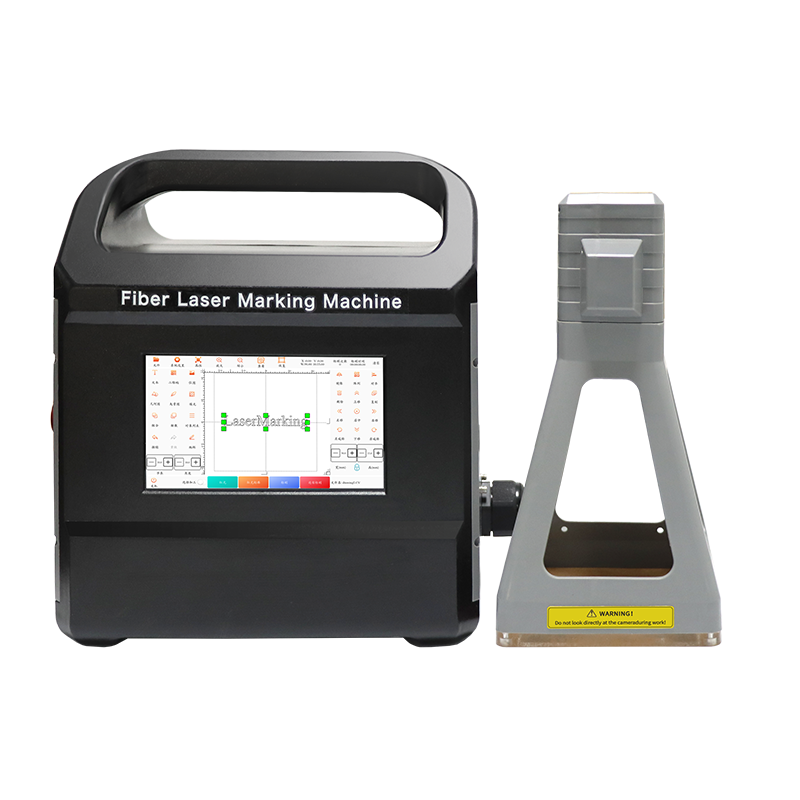

Using and handling a handheld laser marking machine requires proper setup, operation, and safety precautions to ensure efficiency and prevent accidents. Below is a step-by-step guide:

1. Safety Precautions

Wear Protective Gear: Use laser safety goggles to protect your eyes from reflected beams.

Avoid Skin Exposure: Never point the laser at skin or reflective surfaces.

Ventilation: Work in a well-ventilated area to avoid inhaling fumes (especially when marking plastics or coated metals).

Keep Away Flammables: Ensure no flammable materials are nearby.

2. Setup & Preparation

Power Connection: Plug the machine into a stable power source.

Check Laser & Lens: Ensure the laser lens is clean and undamaged.

Install Software (if applicable): Some models require software for design input (e.g., CorelDraw, EzCad).

Material Compatibility: Confirm the material is suitable for laser marking (metals, plastics, wood, etc.).

3. Basic Operation Steps

Turn On the Device: Power on the machine and wait for initialization.

Adjust Settings (via control panel or software):

Power (%): Adjust based on material hardness (higher for metals, lower for plastics).

Speed (mm/s): Slower speed = deeper marks.

Frequency (Hz): Adjust for different materials (e.g., 20-50kHz for metals).

Focus the Laser: Adjust the distance between the laser head and the material (usually 5-20cm, depending on the focal length).

Test Marking: Perform a test run on a scrap piece to fine-tune settings.

Start Marking: Hold the device steadily or use a fixture for precision. Press the trigger (or start via software).

Monitor Progress: Ensure consistent marking quality.

4. Post-Operation

Turn Off Properly: Shut down the laser and disconnect power.

Clean the Lens: Use a soft, lint-free cloth with alcohol to remove debris.

Inspect for Damage: Check cables, lenses, and cooling systems (if applicable).

5. Maintenance Tips

Regularly clean the laser lens and ventilation filters.

Check cooling systems (if water-cooled) to prevent overheating.

Store in a dry, dust-free environment.

6. Troubleshooting Common Issues

Faint Marks: Increase power or reduce speed.

Burnt Edges: Lower power or increase speed.

Misalignment: Recalibrate the laser focus.

Overheating: Ensure proper cooling and ventilation.

7. Applications

Metals: Serial numbers, logos, barcodes.

Plastics: Product labels, QR codes.

Wood/Leather: Decorative engravings.