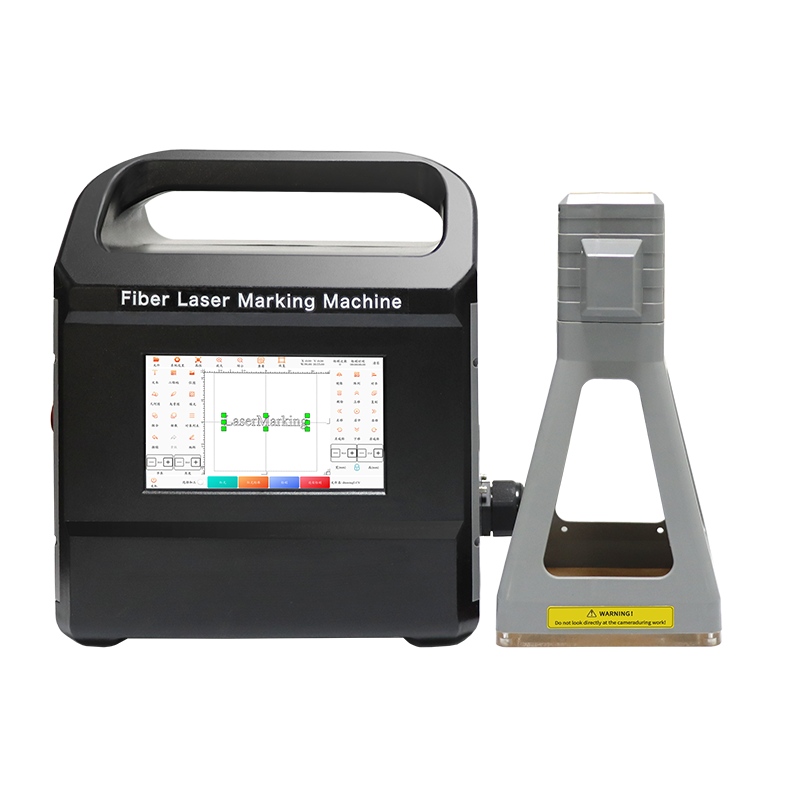

Using a handheld laser marking machine involves several steps to ensure safe and effective operation. Here's a general guide:

1. Safety Precautions

Wear laser safety goggles to protect your eyes from reflected beams.

Avoid pointing the laser at reflective surfaces or people.

Work in a well-ventilated area if marking materials that produce fumes.

Keep flammable materials away from the laser.

2. Setup & Preparation

Charge/Power the Device: Ensure the battery is fully charged or connect it to a power source.

Install Software (if applicable): Some models require connecting to a computer to upload designs.

Adjust Focus: Set the correct focal distance (usually by rotating the lens or adjusting the head).

3. Load or Design the Marking Content

Preloaded Patterns: Some handheld lasers have built-in fonts/symbols.

Custom Designs: Use companion software (like LightBurn, EzCad) to import/design graphics, text, or barcodes.

Adjust Settings: Set power (%), speed (mm/s), and frequency (Hz) based on material (test on scrap first).

4. Marking Process

Position the Laser: Hold the device steady or use a fixture for alignment.

Start Marking: Press the trigger or start button (some models require a foot pedal).

Move Evenly: For large areas, move the laser at a consistent speed to ensure uniform marking.

5. Post-Marking

Inspect the mark for clarity and depth.

Adjust settings if needed for better results.

Clean the lens periodically with a microfiber cloth to maintain beam quality.

6. Maintenance

Store in a dry, dust-free environment.

Check for loose connections or lens damage.

Replace consumables (like batteries or lenses) as needed.

Common Materials & Applications

Metals (anodized, coated): High contrast marks.

Plastics: Adjust power to avoid melting.

Wood & Leather: Engrave logos or text.

Glass & Ceramics: Use lower power to prevent cracking.