Of course. Here is a detailed overview of using handheld laser marking machines in the processing of handicrafts, covering their benefits, applications, considerations, and more.

Handheld Laser Marking Machines: Revolutionizing Artisanal Handicrafts

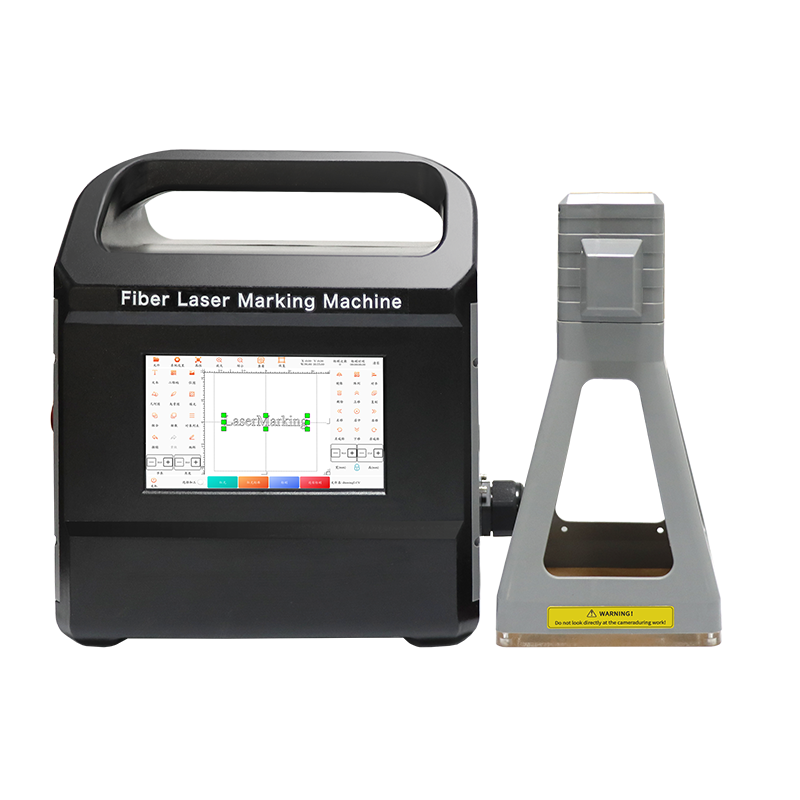

A handheld laser marking machine is a portable device that uses a focused laser beam to alter the surface of a material, creating permanent marks, designs, logos, or text without physical contact. For artisans and crafters, this technology has opened up a new world of possibilities for adding precision, personalization, and professionalism to their work.

How It Works in a Handicraft Context:

Design Creation: The artisan creates or imports a design (e.g., a signature, logo, intricate pattern, or text) into specialized marking software on a computer.

Connection & Setup: The handheld laser marker is connected to the computer (via USB or Wi-Fi) and configured for the specific material (e.g., wood, leather, glass).

Marking Process: Instead of a fixed bed, the artisan holds the device like a pen or printer. They simply point the laser head at the workpiece and trigger the laser. The device can be used freehand for unique marks or with guides/stencils for consistency. Some advanced models may have a small, built-in camera for precise positioning.

Key Advantages for Handicraft Processing

Unmatched Precision & Detail: Lasers can reproduce incredibly complex and delicate designs—from fine filigree on jewelry to detailed portraits on wood—that are difficult or impossible to achieve by hand.

Permanent & High-Quality Marks: The marks are burned or etched into the material itself, making them durable, smudge-proof, and resistant to fading. This enhances the perceived value and longevity of the craft.

Non-Contact Process: The laser does not physically touch the material. This means:

No risk of damaging delicate or fragile items.

No tooling wear and tear (no bits to replace).

Ability to mark on irregular, curved, or hard-to-reach surfaces (e.g., the inside of a bowl, a curved leather bag).

Versatility on Materials: A single machine can work on a vast array of materials common in handicrafts:

Wood & Bamboo: Branding, artwork, personalized signs.

Leather: Logos, patterns, custom text on wallets, bags, and journals.

Acrylic & Plastic: Creating decorative pieces, name tags, and intricate models.

Glass & Ceramics: Etching designs, monograms, or patterns on vases, cups, and ornaments.

Fabric & Paper: Delicate etching on premium paper products or certain natural fabrics (with care).

Coated Metals, Stone, and Shell.

Efficiency & Scalability for Personalization: This is a game-changer. Artisans can easily create one-off, customized pieces without the setup time or cost of traditional methods. Personalizing a name or date takes seconds, making it perfect for wedding gifts, commemorative items, and personalized merchandise.

Professional Branding: Easily add a professional logo, signature, or website URL to every piece, strengthening brand identity.

Popular Applications in Handicrafts

Personalized Gifts: Custom names, dates, messages, and fingerprints on jewelry, photo frames, keychains, and Christmas ornaments.

Artisan Branding: Burning a distinct logo or signature onto finished products (e.g., on the bottom of a ceramic mug or the back of a leather wallet).

Intricate Decoration: Adding complex geometric patterns, nature scenes, or mandalas to wooden boxes, guitar bodies, and leather covers.

Textural Contrast: Creating raised or sunken areas by varying laser power and speed, adding a tactile element to a piece.

Prototyping & Model Making: Precisely cutting or engraving small parts for scale models or intricate art installations.

Important Considerations Before Using One

Material Limitations & Safety:

PVC/Vinyl and Chrome-Tanned Leather: NEVER laser these materials. They can release highly toxic chlorine gas when heated.

Always research if a material is laser-safe. Test on a scrap piece first.

Safety is Paramount:

Protective Eyewear: The reflected laser light can cause permanent eye damage. Everyone in the room must wear laser safety goggles rated for the specific wavelength of the machine.

Adequate Ventilation & Fume Extraction: Lasering produces smoke and fumes. Always use the machine in a well-ventilated area, preferably with an external fume extractor to protect your lungs and prevent residue from settling on the workpiece.

Initial Investment: While more affordable than industrial systems, a good-quality handheld fiber laser marker is a significant investment ($1,000 - $5,000+).

Learning Curve: Operating the software (e.g., LightBurn) and understanding the correct settings (power, speed, frequency) for different materials requires practice and experimentation.