- Executive Summary

- How Handheld Laser Marking Works

- Key Applications in Engineering & Construction

- 1. Asset Identification and Traceability

- 2. Safety and Compliance

- 3. Quality Control and Inspection

- 4. As-Built Documentation and Facility Management

- 5. Layout and Surveying Points

- Advantages Over Traditional Marking Methods

- Technical Considerations for Selection

- Limitations and Challenges

Of course. Here is a detailed overview of handheld laser marking machines in the field of engineering and construction.

Executive Summary

Handheld laser marking machines have transitioned from factory-floor tools to indispensable assets in the dynamic environments of engineering and construction. Their ability to create permanent, high-contrast marks on a vast array of materials directly on-site revolutionizes asset identification, traceability, safety, and quality control processes. They offer a clean, efficient, and versatile alternative to traditional methods like paint stencils, engravers, or labels.

How Handheld Laser Marking Works

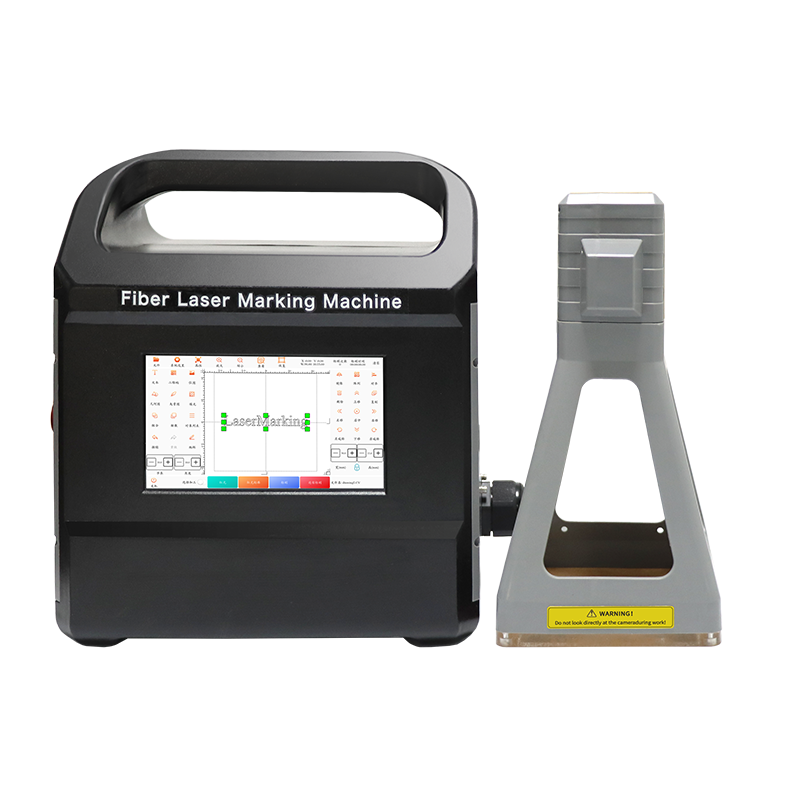

A handheld laser marker is a portable unit consisting of a main control system (often in a backpack or portable case) and a handheld "gun" or pen-like device. The system uses a fiber laser source (most common for metals) or a MOPA laser (for more color options on metals and plastics). The laser beam is directed through mirrors and lenses inside the handpiece onto the material's surface.

The laser energy alters the surface's properties through several processes:

Annealing: Heats the metal to create a dark, permanent oxide layer without removing material. Ideal for stainless steel and titanium.

Engraving/Etching: Vaporizes a tiny amount of material to create a deep or shallow indent.

Foaming: For plastics, it heats the material to create gas bubbles, resulting in a light-colored mark.

Carbonization: For plastics and composites, it burns the surface slightly to create a dark mark.

The user typically designs the mark (text, barcode, QR code, logo, serial number) on connected software, aims the handpiece, and triggers the laser, which marks the surface in seconds.

Key Applications in Engineering & Construction

1. Asset Identification and Traceability

This is the primary application. Every piece of critical infrastructure or equipment can be permanently marked with a unique identifier.

Structural Steel: Marking I-beams, rebar, and plates with heat numbers, grade, size, lot number, and project ID for full traceability from mill to installation.

Pipes and Tubing: Marking material grade, pressure rating, thickness, and destination before they are insulated or buried.

Valves, Flanges, and Fittings: Marking specifications and flow directions to prevent installation errors.

2. Safety and Compliance

Permanent markings ensure critical safety information is always visible and cannot be worn off or painted over.

Load Ratings: Directly marking load limits on lifting equipment, shackles, and crane components.

Electrical Hazard Warning: Marking panels and conduits with voltage warnings.

Pressure Ratings: Marking on vessels and pipes.

Compliance Marks: Adding CE, UKCA, or other certification marks to fabricated components.

3. Quality Control and Inspection

Weld Tracing: Permanently marking a unique ID next to every weld. This allows inspectors to log reports, X-rays, and certifications directly to that specific weld on a digital map of the project.

Date/Shift Codes: Marking components with the manufacture or installation date and shift code for precise quality tracking.

Acceptance Marks: Marking components that have passed inspection.

4. As-Built Documentation and Facility Management

QR Code/Barcode Integration: Marking a QR code on an asset (e.g., a pump, valve, or electrical panel). Field technicians can scan the code with a phone to instantly pull up the asset's entire history: installation date, maintenance manuals, service records, and 3D model data from BIM.

BIM Integration: Linking physical assets in the field directly to their digital twins in the Building Information Model (BIM).

5. Layout and Surveying Points

Precision Marking: Creating small, precise reference points on concrete floors or structural members for layout, alignment, and installation guidance. This is more permanent and accurate than chalk or pencil.

Advantages Over Traditional Marking Methods

| Method | Disadvantages | Handheld Laser Advantage |

|---|---|---|

| Paint Stencils | Fades, chips, peels. Messy. Requires consumables (paint). | Permanent, clean, no consumables. |

| Engravers / Scribers | Slow, requires physical contact (can damage material). Operator fatigue. | Non-contact, fast, minimal operator effort. |

| Labels / Adhesive Tags | Can fall off due to moisture, heat, or chemical exposure. Not permanent. | Permanent mark directly on the asset itself. |

| Ink Jet Printing | Ink can smear or fade. Requires consumables (ink). Not suitable for rough surfaces. | No consumables, mark is resistant to environmental factors. |

Technical Considerations for Selection

Laser Type & Power:

Fiber Laser (20W-50W): The standard for marking most metals (steel, aluminum, titanium, brass). Excellent for annealing and engraving.

MOPA Fiber Laser: Offers more flexibility on metals, allowing for different colors (e.g., black, red, green marks on stainless steel) and better results on plastics.

UV Laser: For specialized applications on glass, certain plastics, and PCBs, but less common in construction.

Portability & Power Source: Look for lightweight systems with long-lasting battery options (lithium-ion) for true cordless operation in the field. Some systems use a portable case with a built-in battery.

Software: User-friendly software is critical. It should easily import data from Excel or CAD files for batch serialization and support all standard barcodes and 2D codes.

Durability: The handpiece and main unit should be ruggedized to withstand typical site conditions (dust, moisture, minor impacts).

Safety: CRITICAL. Class 4 lasers are serious eye and skin hazards. Systems must include:

Laser Safety Glasses specific to the laser's wavelength.

Area Guarding to prevent accidental exposure to others.

Key Switch and clear safety training protocols.

Limitations and Challenges

Material Limitations: Not all materials mark well. For example, untreated concrete and wood are generally poor candidates for fiber lasers. Test samples are always recommended.

Surface Condition: Heavily rusted, oily, or uneven surfaces can result in poor mark contrast or consistency. Surfaces may need cleaning first.

Initial Cost: The upfront investment is significant compared to a paint marker or label printer.

Safety Protocols: Requires strict adherence to laser safety procedures, which adds a layer of complexity to site operations.