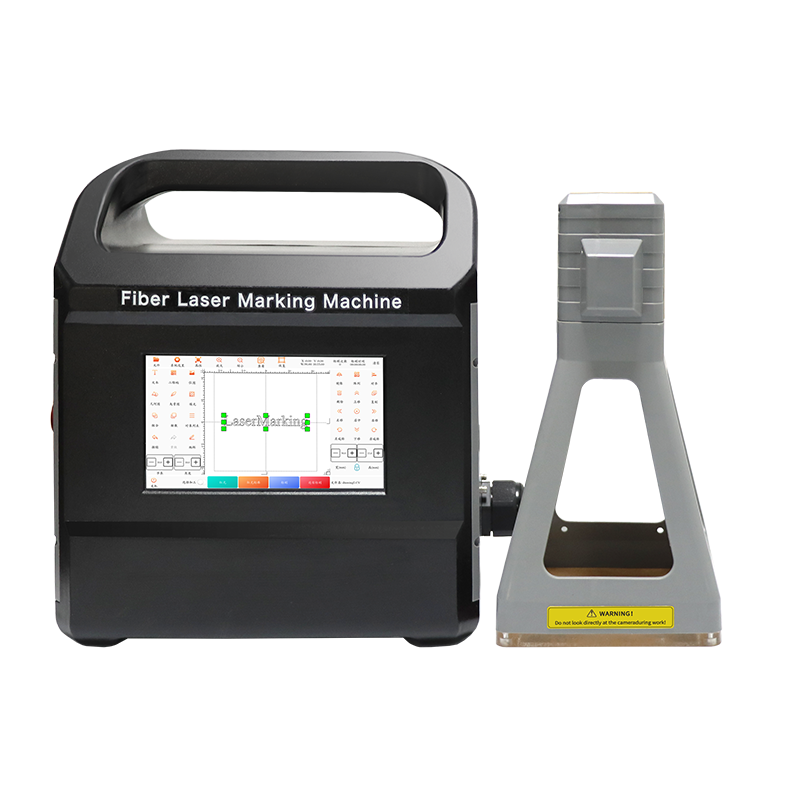

A Handheld Fiber Laser Marking Machine is a portable, high-precision device used for engraving, etching, or marking various materials with exceptional accuracy. It leverages fiber laser technology, making it ideal for industrial, commercial, and creative applications.

Key Features:

✔ Portable & Handheld Design – Easy to operate and maneuver for marking on large or irregularly shaped workpieces.

✔ High Precision & Speed – Delivers fine, permanent marks with micron-level accuracy.

✔ Fiber Laser Source – Typically 20W/30W/50W, with a 1064nm wavelength, optimized for metals and some plastics.

✔ Wide Material Compatibility – Works on stainless steel, aluminum, copper, brass, titanium, plastics, ceramics, and more.

✔ User-Friendly Software – Supports AutoCAD, CorelDraw, Photoshop, and other graphic formats for custom designs.

✔ Long Lifespan – Fiber laser modules last 100,000+ hours, ensuring durability.

✔ Low Maintenance – No consumables (like inks or bits), reducing operational costs.

Applications:

Industrial Part Marking (Serial numbers, barcodes, QR codes)

Jewelry & Personalized Engraving (Names, logos, intricate designs)

Electronics & PCB Marking (Circuit boards, chips)

Automotive & Aerospace (VIN numbers, component tracking)

Medical Devices & Tools (Surgical instruments, stainless steel tags)

Advantages Over Traditional Methods:

✅ Non-contact process – No physical wear on materials.

✅ Eco-friendly – No chemicals or inks required.

✅ High-speed marking – Seconds per mark, ideal for mass production.

✅ Permanent & Resistant – Marks withstand heat, abrasion, and corrosion.

Considerations Before Purchase:

Material Suitability – Best for metals; limited effectiveness on non-metallic materials like wood or glass.

Safety – Requires protective eyewear (laser safety goggles).

Budget – Higher initial cost than CO₂ or diode lasers but more efficient long-term.