Fiber laser marking machines are widely used in sheet metal processing workshops for their precision, speed, and versatility. Here’s how they are applied in sheet metal manufacturing and processing:

1. Applications in Sheet Metal Processing

Fiber laser markers are used for:

Part Identification – Engraving serial numbers, QR codes, barcodes, and logos for traceability.

Labels & Branding – Marking company logos, product names, or compliance symbols (CE, UL, etc.).

Cutting & Etching Guidelines – Marking reference lines for bending, cutting, or drilling.

Anodized & Coated Metals – Permanent marks on anodized aluminum, galvanized steel, or painted surfaces.

Anti-Counterfeiting Marks – Micro-text or hidden markings for security.

2. Advantages in Sheet Metal Workshops

High Precision – Produces fine, clean marks (as small as 0.01mm) without damaging the material.

Non-Contact Process – No physical force reduces sheet metal deformation.

Fast Marking Speed – Up to thousands of characters per minute, ideal for mass production.

Durable Marks – Resistant to abrasion, heat, and chemicals.

Low Maintenance – Fiber lasers have a long lifespan (100,000+ hours) with minimal upkeep.

Automation-Friendly – Can be integrated into CNC machines or robotic arms for inline marking.

3. Common Materials Marked

Stainless Steel (304, 316, etc.)

Aluminum & Anodized Aluminum

Carbon Steel & Galvanized Steel

Brass & Copper

Titanium & Other Alloys

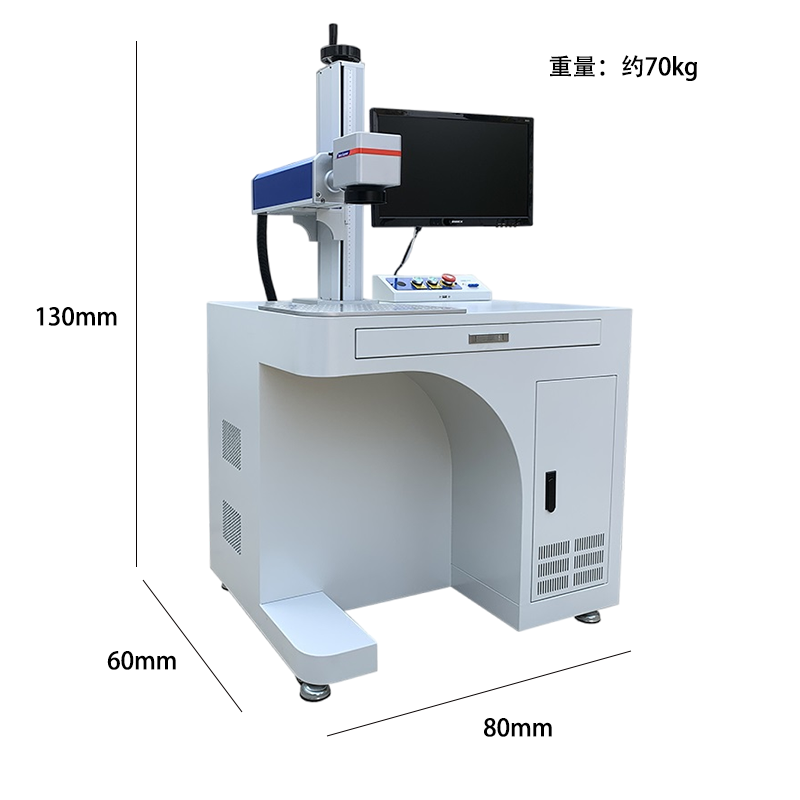

4. Typical Machine Specifications for Sheet Metal Work

Laser Power: 20W – 50W (sufficient for most sheet metal marking).

Wavelength: 1064nm (ideal for metals).

Marking Area: 100x100mm to 300x300mm (or larger for big sheets).

Software Compatibility: Supports AutoCAD, CorelDraw, DXF files, and barcode generation.

5. Integration in the Workshop

Standalone Units – For manual or small-batch marking.

CNC Integration – Works with laser cutters or punching machines.

Conveyor Systems – For automated high-volume marking.

6. Maintenance & Safety

Ventilation: Required for fume extraction when marking coated metals.

Lens Cleaning: Regular cleaning ensures consistent marking quality.

Safety Enclosures: Protects operators from laser exposure.