Fiber Laser Marking Machine Installation & Operation Process

Installation Process

1. Unpacking and Inspection

Carefully unpack the machine and check all components against the packing list

Inspect for any visible damage during transportation

Verify all accessories are included (power cables, USB cables, air pump if applicable, etc.)

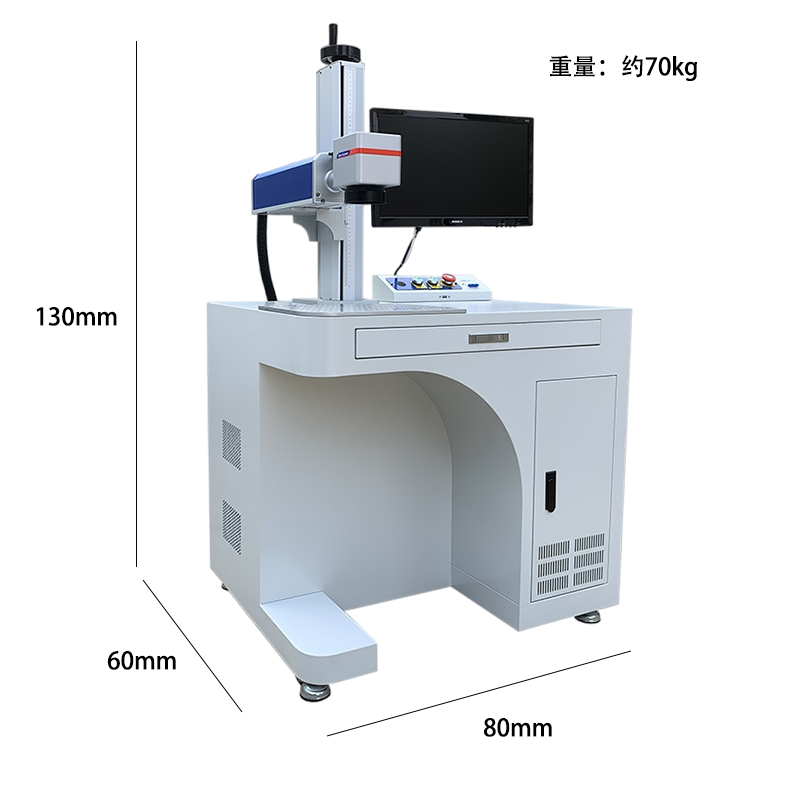

2. Machine Placement

Place the machine on a stable, vibration-free work surface

Ensure adequate space around the machine for ventilation and operation

Keep away from direct sunlight, moisture, and extreme temperatures

3. Electrical Connections

Connect to proper power supply (check voltage requirements - typically 110V/220V)

Ensure proper grounding of the machine

Connect to computer if required (via USB or network)

4. Cooling System Setup

For water-cooled models: fill with distilled water and check circulation

For air-cooled models: ensure ventilation openings are unobstructed

5. Software Installation

Install the marking software on the connected computer

Install necessary drivers

Configure software settings according to machine specifications

Operation Process

1. Startup Procedure

Turn on main power switch

Start the cooling system (if separate)

Power on the laser marking machine

Launch the marking software

2. Parameter Setting

Adjust parameters based on material:

Laser power (typically 20-100%)

Marking speed (mm/s)

Frequency (kHz)

Filling type (hatching, outline, etc.)

Q-switch settings (if applicable)

3. Focus Adjustment

Place sample material on work table

Adjust Z-axis to achieve proper focal length (use focus tool if provided)

Test mark to verify focus quality

4. Marking Operation

Import or create design in the marking software

Position material on work table (use fixtures if necessary)

Set origin point (manual or automatic)

Preview marking path (simulation if available)

Start marking process

5. Shutdown Procedure

Turn off laser power

Close marking software

Power down the machine

Maintain cooling system for recommended time (if water-cooled)

Turn off main power

Safety Precautions

Always wear appropriate laser safety glasses

Never operate with protective covers removed

Keep flammable materials away from work area

Follow all manufacturer safety guidelines

Provide proper ventilation for fumes when marking certain materials

Maintenance

Regular lens cleaning (use proper cleaning solution and techniques)

Check and clean ventilation filters

Monitor cooling system (water level, temperature)

Lubricate moving parts as recommended

Schedule professional maintenance as required