Laser marking machines are versatile tools used across various industries for precision marking, engraving, and etching. Different types of laser markers utilize distinct laser technologies, each suited for specific materials and applications. Here are breakdown of the common types and their typical uses:

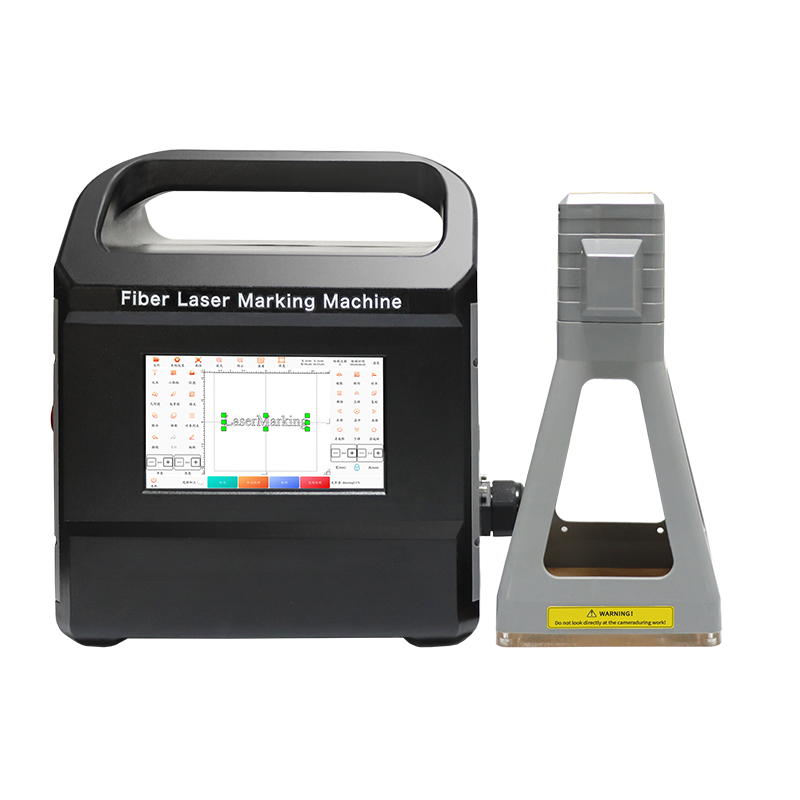

1. Fiber Laser Marking Machines

Laser Type: Solid-state (Fiber laser, 1064 nm wavelength).

Best For: Metals (stainless steel, aluminum, titanium, brass), some plastics, and coated materials.

Applications:

Industrial part serial numbers, barcodes, and QR codes.

Aerospace and automotive component marking.

Jewelry engraving and tool identification.

Advantages: High speed, long lifespan, low maintenance, and excellent for deep engraving.

2. CO₂ Laser Marking Machines

Laser Type: Gas laser (CO₂, 10.6 μm wavelength).

Best For: Non-metallic materials (wood, acrylic, glass, leather, plastics, rubber, ceramics).

Applications:

Packaging (food, pharmaceuticals).

Woodworking and signage.

Medical device marking (plastic components).

Advantages: Ideal for organic materials; cost-effective for large-area engraving.

3. UV Laser Marking Machines

Laser Type: Ultraviolet (355 nm wavelength).

Best For: Sensitive materials requiring "cold marking" (no heat damage).

Applications:

Electronics (PCB marking, semiconductor chips).

Medical devices and glassware.

High-contrast marks on plastics and silicone.

Advantages: Minimal thermal impact, high precision for delicate materials.

4. Green Laser Marking Machines

Laser Type: DPSS (532 nm wavelength).

Best For: Highly reflective metals (copper, gold), plastics, and sensitive materials.

Applications:

Jewelry and precision instrument engraving.

Electronics (IC chips, LCD screens).

Advantages: Reduced reflectivity issues, fine detail capability.

5. YAG Laser Marking Machines

Laser Type: Solid-state (Nd:YAG, 1064 nm).

Best For: Metals and some plastics (legacy technology, largely replaced by fiber lasers).

Applications:

Older industrial systems for metal part marking.

Advantages: Robust but less efficient than fiber lasers.

Key Factors in Choosing a Laser Marking Machine

Material: Match the laser type to the material (e.g., fiber for metals, CO₂ for organics).

Marking Depth: Fiber lasers excel in deep engraving; UV lasers are surface-level.

Speed/Precision: UV/green lasers offer finer detail; fiber/CO₂ are faster for bulk marking.

Budget: CO₂ lasers are affordable for non-metals; fiber lasers have higher upfront costs but lower maintenance.

Industry-Specific Examples

Medical: UV lasers for biocompatible markings.

Automotive: Fiber lasers for VIN numbers and metal parts.

Electronics: Green/UV lasers for circuit boards.

Aerospace: Fiber lasers for high-durability part IDs.