Laser cleaning technology refers to the process of using high power density laser beam to irradiate the workpiece surface, so that the dirt, rust spots or coatings on the surface can evaporate or peel off instantaneously, thus achieving cleaning and purification. This cleaning equipment is a new generation of high-tech products for surface treatment, which is easy to install, operate and realize automation. It is easy to operate. It can be cleaned without chemical reagent, medium, dust and water by switching on the power supply. It can remove the resin, paint, oil stain, dirt, rust, coating, plating and oxide layer on the surface of objects. It is widely used in the industry, covering ships, auto repair, rubber molds, high-end machine tools, rails and environmental protection

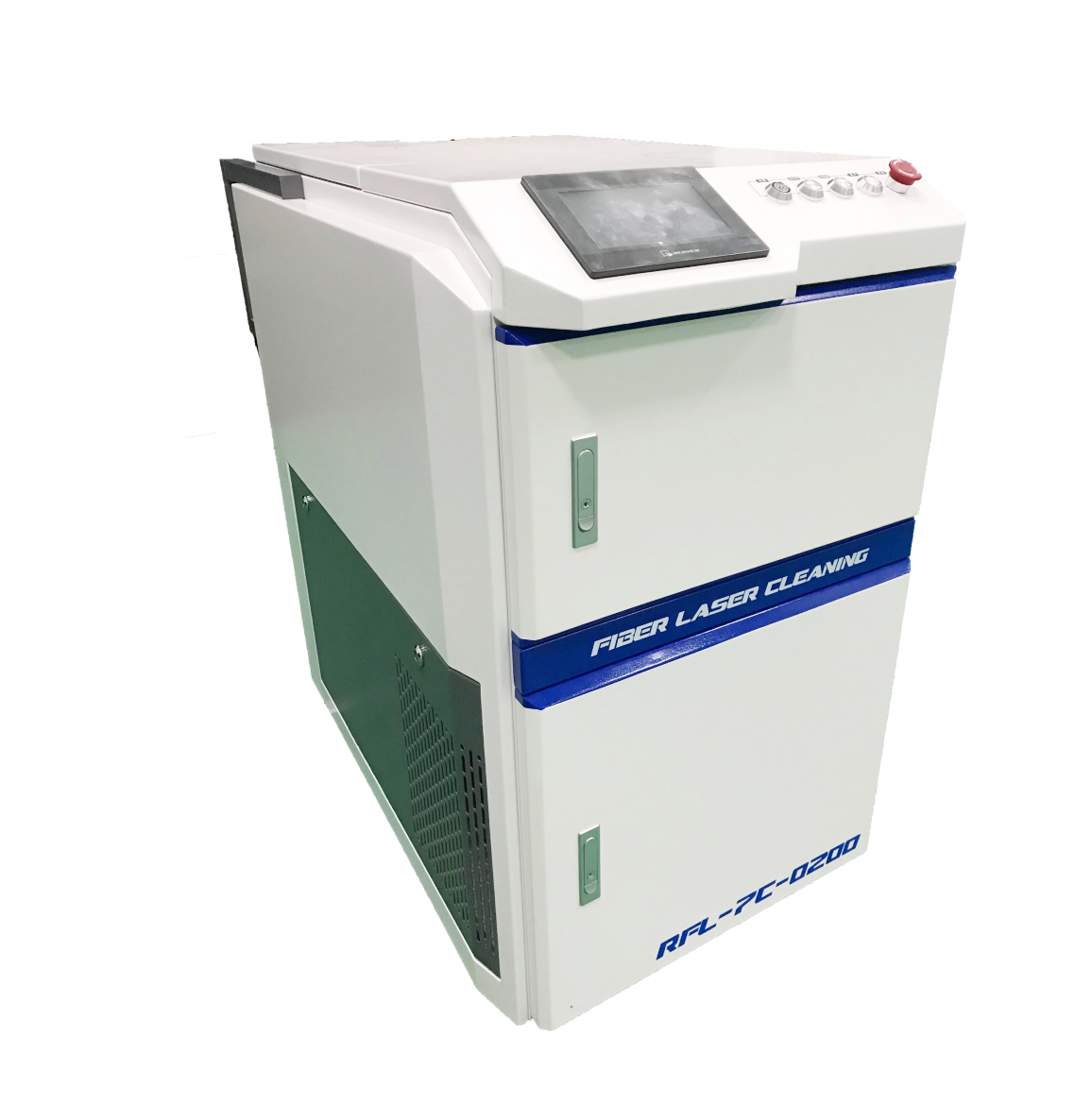

Pulse laser cleaning machine

The hand-held laser cleaning machine adopts high power fiber laser, integrates the photoelectric system with the appearance hand-held design, and outputs the laser from the numerical control panel, which is characterized by high precision, high efficiency, high cost performance, etc. It can remove the resin, paint, oil stain, stain, dirt, rust, coating, plating and oxide layer on the surface of objects, and is widely used in the industry, including ships, automobile repair, rubber mold, high-end machine tools, rails and environmental protection.

Laser cleaning gun head

1. Non contact cleaning, without damaging the part matrix.

2. Precise cleaning, which can achieve selective cleaning in precise position and size.

3. No chemical cleaning solution, no consumables, safe and environmentally friendly.

4. It is easy to operate, and can be powered on. It can be manually or with a manipulator to achieve automatic cleaning.

5. High cleaning efficiency and time saving.

6. The laser cleaning system is stable and almost maintenance free.

Multiple laser options

Different brands, different laser power options

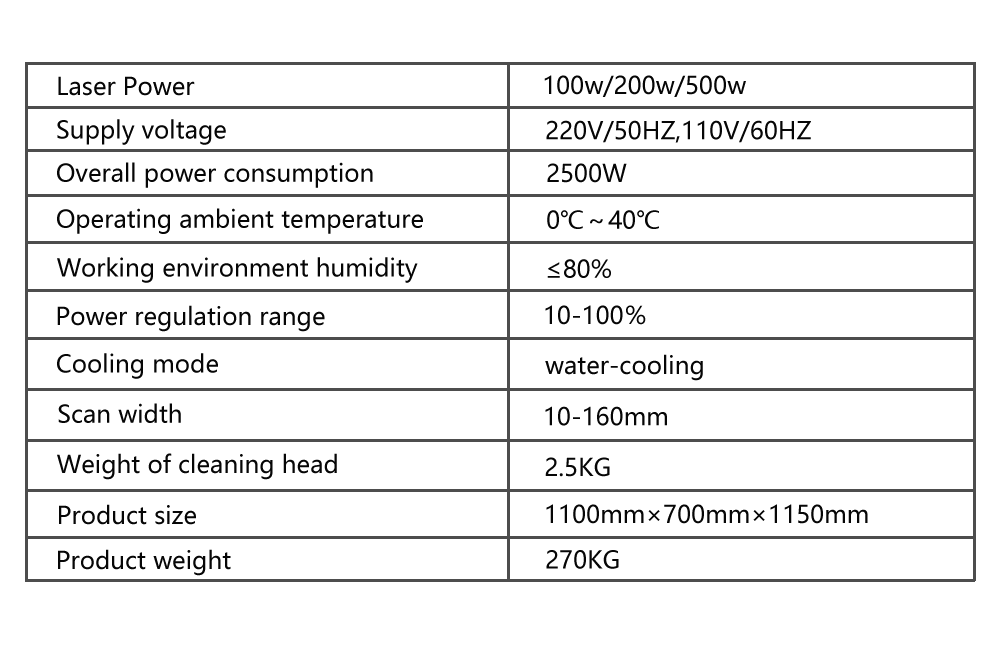

The higher the power of 100W/200W/500W, the faster the speed, and the higher the cleaning efficiency

Add WeChat friends